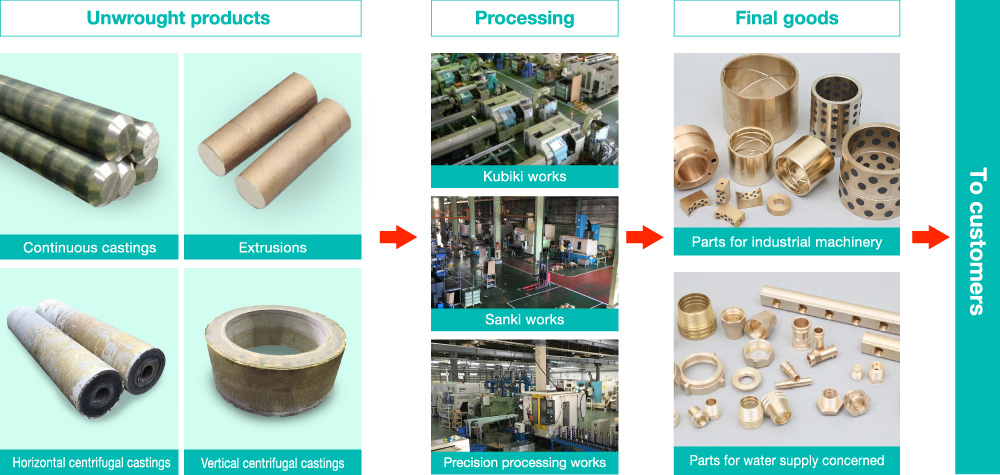

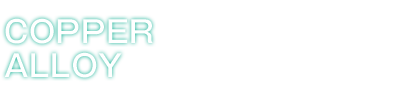

The first process of recycle that from scraps to cast products.

Collected scraps and or raw materials are molten and then cast. And so , centrifugal castings and continuous castings are supplied to users. Those castings are less than sand castings for the defects like porosities. Therefore those castings are higher quality products. We supply such as an unwrought products with high class chemical analyzers and many measurement equipments as parts of ships, industrial machineries and related water supply etc.

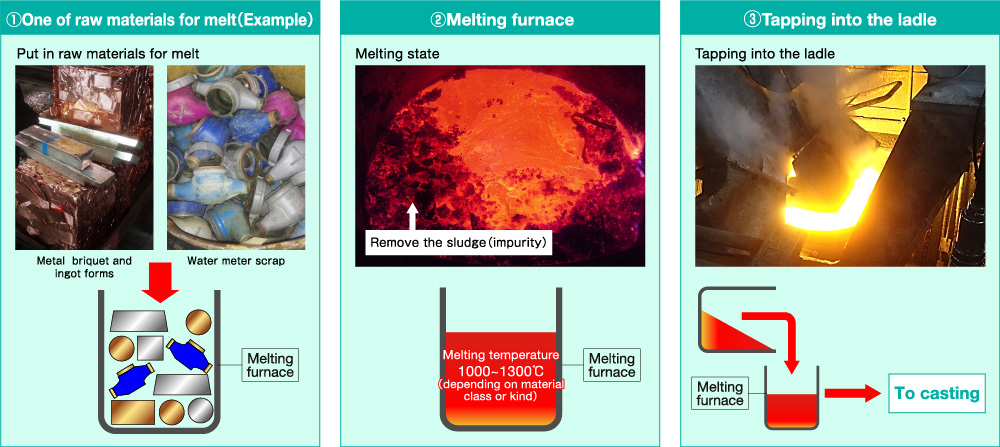

This casting way is that

molten metal is poured into the holding furnace and then rapidly solidified in a graphite. And solidified products are drawn out continuously .

In this way, solid round, hollow, polygon and various shape bars are castable.

| Characteristic | ●Suitable for muss production ●Be good to reduce the cost since productivity is higher ●Quality is higher and stable |

|---|

This way that

Molten metal is poured into on rotating metal mold and since in accordance with solidifying toward internal side by the cooling from metal mold the defects is centralized to internal side, high quality products is gotten.

| Characteristic | ●Fine and high quality ●Good yield rate ●For small quantity lot |

|---|

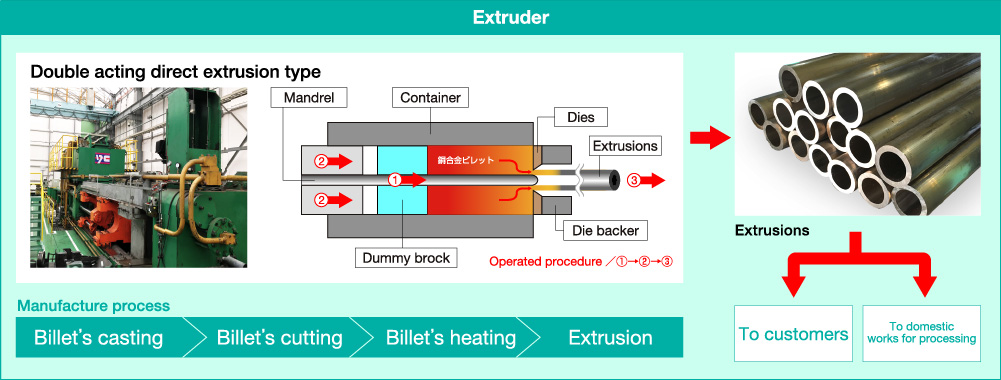

We supply high quality extrusions that is excluded from billet. This billet is produced by a continuous or semi continuous casting ourselves. We supply such as an unwrought products with high class chemical analyzers and many measurement equipments as parts of industrial machineries and as for forging.

We process and machine continuous castings , centrifugal castings and extrusions produced by ourselves with recent NC model and CNC lathe with high accuracy to supply as parts for industrial machineries and water supply concerned .